Bob Ortblad says the IBR is hiding a serious “boulder” problem that threatens the feasibility of the Columbia River bridge design

Editor’s note: Opinions expressed in this letter to the editor are those of the author alone and do not reflect the editorial position of ClarkCountyToday.com

The Interstate Bridge Replacement Program’s (IBR) I-5 Bridge replacement project will make the I-205 Abernethy Bridge cost overrun look like a bargain.

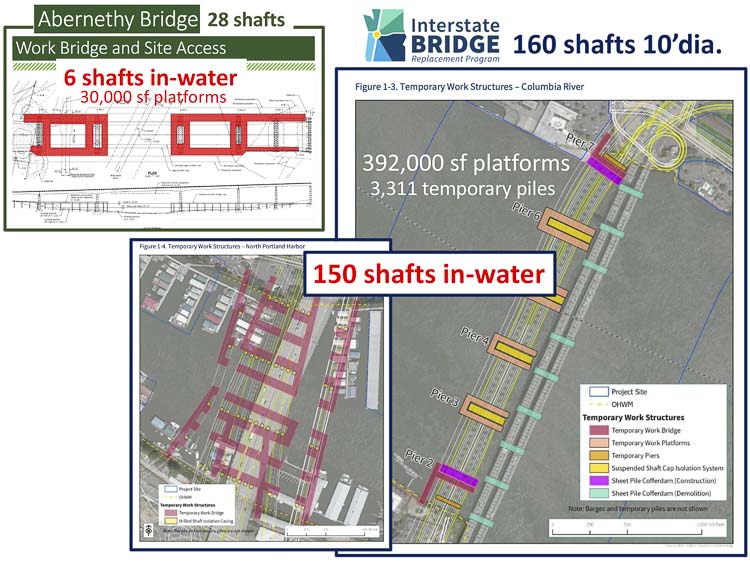

The cost for the Abernethy Bridge has more than tripled, from $248 million to $812 million, and continues to rise. A significant portion of this increase is attributed to the bridge’s 28 drilled shafts, of which only 6 shafts are in the Willamette River.

In comparison, the IBR plans to use 160 drilled shafts, with 150 of them situated in the more challenging Columbia River. Most of these shafts will be far from ether riverbank, making their construction more difficult and costly. The IBR’s shafts will necessitate 3,311 temporary piles and 392,000 square feet of temporary platforms. These will require a costly fleet of barges, tugs, marine cranes, impact pile drivers, vibratory piles drivers, and a very specialized 100-ton shaft oscillator.

While each Abernethy Bridge shaft took about one month to complete, the IBR claims it can finish the more difficult shafts in just 5 days each, completing all 160 shafts in 800 nonconsecutive days. Additionally, the IBR claims that drilling can occur year-round. However, according to the U.S. Army Corps of Engineers and Oregon Fish & Wildlife, there is a four-month in-water work window from November 1 to February 28. The IBR also estimates it can complete the Columbia River bridges in 4 to 7 years and the North Portland Harbor bridges in 4 to 10 years.

It is doubtful the IBR can complete a shaft in five days and drill year-round, ignoring a four-month in-water work window. The Abernathy Bridge was restricted by an in-water work window, and each shaft took 30 days. Based on this, 160 shafts, at 30 days each, would require 4,800 nonconsecutive days to complete, potentially adding a decade to the construction timeline. Conservatively assuming Abernathy Bridge’s 28 drilled shafts are 25% of the current $812 million cost, then each shaft would cost about $7.25 million. At $7.25 million/shaft IBR’s 160 shafts will cost over $1 billion.

In 2012, the Columbia River Crossing estimated each shaft would cost $1.25 million ($2.5 million today) and spent $4.2 million to test a few piles and a single shaft. Malcolm Drilling Co. tried to sink a single 10-foot diameter steel casing 250 feet deep on Hayden Island. In a trade journal, Malcolm Drilling recounted its failure to sink this test shaft due to boulders.

“However, during excavation and casing installation of the 10-foot diameter shafts, an unknown layer of very dense boulders in a “fixed condition,” resulted in damage to an installation tooth ring to the point that excavation to the planned shaft depth was impossible.”

The IBR is hiding a serious “boulder” problem that threatens the feasibility of the Columbia River bridge design. IBR’s Supplemental Environmental Impact Statement includes 26 technical reports, but a critically important geotechnical report is missing, and the IBR has offered no explanation. I filed a Public Disclosure Request and obtained IBR’s “Geotechnical Data Report” dated May 2024. This report describes the encounter of many boulders and cobbles in a 200-foot layer of sediment. The report referenced boulders 106 times and cobbles 175 times.

Shockingly, the IBR has fraudulently disqualified an immersed tunnel alternative that would eliminate the need for drilled shafts. Similar to a floating bridge, an immersed tunnel is supported by displacing its weight, according to Archimedes’ principle. This design is faster to build, could potentially save $1 billion associated with drilled shafts, and would also be more earthquake-resilient than a foundation based on drilled shafts.

Bob Ortblad MSCE, MBA

Seattle

Also read:

- Expect delays on northbound I-5 near Ridgefield through May 9Northbound I-5 travelers near Ridgefield should expect delays through May 9 as crews work on improvements at the Exit 14 off-ramp to support future development.

- 6-cent gas tax hike central to new transportation deal in WA LegislatureA proposed 6-cent gas tax hike is central to a transportation funding deal under negotiation in the Washington Legislature, aimed at raising $3.2 billion over six years.

- Letter: C-TRAN Board improper meeting conductCamas resident Rick Vermeers criticizes the C-TRAN Board for misusing parliamentary procedure during a controversial vote on light rail.

- Opinion: TriMet’s ‘fiscal cliff’ a caution for Clark County taxpayersRep. John Ley warns that Portland’s financially troubled TriMet transit system could pose major risks to Clark County taxpayers as the I-5 Bridge replacement moves forward.

- Travel Advisory: Expect daytime delays on northbound I-5 near Woodland for guardrail repairs, April 18WSDOT will close the left lane of northbound I-5 near Woodland on Friday, April 18, to repair guardrail and improve driver safety.